Mar-Aug,2009 Inverts Remediation Tests

In March, 2009 TRL had the opportunity to conduct a test in conjunction with two Canadian companies at Nexen Oil Company's Drill Rig #19 136 miles north of Ft. Nelson, B.C. TRl constructed a small test unit and hauled the unit to the test site. Testing was conducted for one day only, due to permit limitations. TRL's test unit processed thick invert contaminated shale cuttings and bentonite drilling muds. The drill hole was 14,000ft deep.

In March, 2009 TRL had the opportunity to conduct a test in conjunction with two Canadian companies at Nexen Oil Company's Drill Rig #19 136 miles north of Ft. Nelson, B.C. TRl constructed a small test unit and hauled the unit to the test site. Testing was conducted for one day only, due to permit limitations. TRL's test unit processed thick invert contaminated shale cuttings and bentonite drilling muds. The drill hole was 14,000ft deep.Drill Rig #19 Test

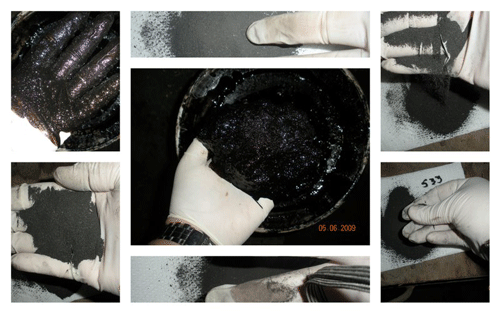

The Nexen test was conducted in March, 2009. The ambient temperature was 15°F (-9.44°C) with a steady 10mph wind component. The test unit was well received. The testing did not go well, due to the surfactant having been left in the pickups of the Canadian parties for 3 days prior to our arrival. The short time allowed for the testing prevented much thawing of the surfactant, resulting in a >50% reduction of the 300,000ppm hydrocarbon levels and about 1/00th of the total surfactant volume intended for the test. The test samples were off the mud tails and were very thick, stank and a pain to deal with at that temperature. Nexen's environmental manager was satisfied with the mechanical aspects of the test unit, but wanted more proof of the chemical side of the recovery--whether or not the sufactant could clean shale cuttings and bentonite drilling muds contaminated with crude, diesel, and whatever else was used to stabilize, control Ph, and to lubricate. The party then proceeded to the headquarters of Chinook Pipelines, Inc. in Pincher Creek, Alberta, characterized as just a few hours down the road--two days later . . . we arrived in Pincher Creek where additional testing was conducted over the next 5 months.Surfactants

The testing was conducted with samples of drill cuttings provided by Nexen and delivered to Pincher Creek, including cuttings from Drill Rig #19. The Rig #19 samples were the most difficult to clean, being exposed to heat and pressure from 14,000ft. Most of the other samples were from holes around 7,000ft deep. Those samples were much easier to clean.Many different surfactants, both high and low temperature, were tried. Considerable delays were encountered, because of the policies of the test labs in Calgary, Alberta. The issues were primarily heat and retention/agitation time. The cleanup goal of <=1,000ppm was met. Non-detect was not achieved, largely due to the very crude treatment process. A final treatment with the single tank test unit brought from Alaska was accomplished in late July, which was deemed successful by Nexen. Wood then left Canada for Alaska to await the outcome of the negotiations between the two Canadian companies. Larry Wood spent 155 days in Canada on the project. Unfortunately, by January, 2010, the Canadians had dissolved their partnership and the project was stopped.

TRL and Invert Remediation

TRL believes that invert remediation will be a good market to develop, as others are doing the job with cement mixers in Texas. However, the recent (2015) drop in oil prices make any remediation difficult to sell.One of the frustrations of this type of work is that the drillers are not going to tell you what they used in their invert mix. Chromium, caustic soda, hydrochloric acid can be additives to conrol Ph and stability, along with the expected non-spec diesel and any crude oil brought up with the mud and shale cuttings. TRL came out of this testing with a good surfactant that worked very well, was economical and could be further enhanced, if necessary. Temperature and retention time was also established. A lot was accomplished that will benefit TRL. Terra Wash™ has the right mix of heating capacity, agitation and flexibility to undertake this type of work. We will endeavor to make opportunity to get equipment into this type of oil field service work. Waste pit remediation is another area that TRL will further investigate.